Үйлчилгээ

Дело клиента

Carbon Screen, Leaching Equipment - Xinhai

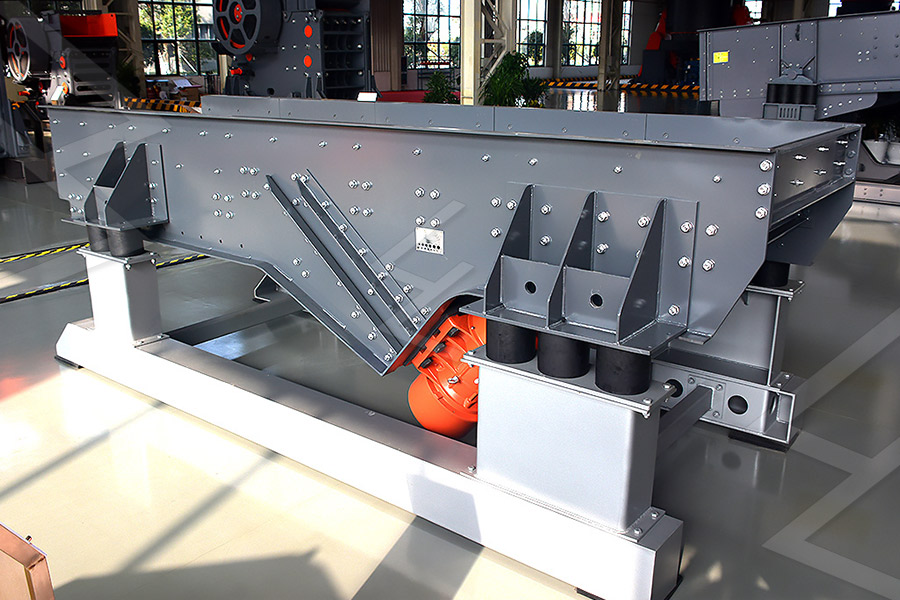

Carbon Screen. [Introduction]: An equipment for separation of carbon and slurry. [Capacity]: 100-500mm. [Improvement]: It adopts an innovative process full peat slurry cyanidation

Үйлчилгээ

Carbon In Pulp Interstage Screening using Submerged High

2018year1month6day The CIL plant design comprises six 10.36m ∅ x 10.67m agitated tanks, each with a single 1.22m x 2.44m Flo-line interstage screen equipped with 0.85mm panels.

Үйлчилгээ

Interstage Screen, CIP / CIL Interstage Screening

Interstage Screen In CIP and CIL Process CIP – Carbon In Pulp. First leaching, and then adsorption. It is suitable for the treatment of oxidized gold ore with low sulfur content and mud content.

Үйлчилгээ

Carbon Screen - Xinhai

Carbon screen is the core equipment of pulp and activated carbon separation applied in carbon leaching tank. It has advantages of advanced design, not easy to block, compact structure, easy to repair.

Үйлчилгээ

Carbon Screen - xinhaiepc

Carbon Screen Mineral Processing EPC+M+O Providing optimized solutions for your mine, one-stop service for mineral processing plant! Product Xinhai mineral processing equipment mainly include: grinding equipment,

Үйлчилгээ

carbon screen system cil

Carbon Screen System Cil mayukhportfolio.co. Gold ore Carbon-In-Leaching (CIL) processing technology TON The Main features of the CIL system: 1. CIL tanks Loaded

Үйлчилгээ

carbon screen system cil

2023year7month23day Almost every imaginable type of screen has been tried for this application, with some types being much more successful than the rest. 3. Carbon-In-Leach (CIL):

Үйлчилгээ

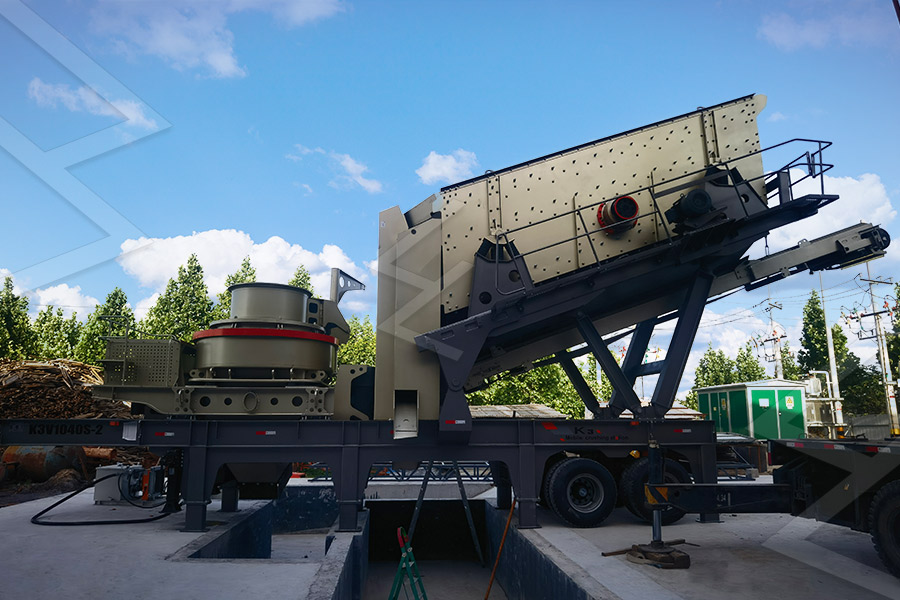

Rotaspiral Screen CEC Mining Systems

The CX-PSS Rotaspiral Screen (RS) is an evolution for a conventional drum screen system that removes wood fibre, trash, and oversize particles from slurried, processed ores down to 75 microns. It has been employed

Үйлчилгээ

Evaluation and Optimization of Metallurgical Performance

2016year9month4day A countercurrent system such as CIL or CIP with interstage carbon transfer will result in a far different distribution. For example, if a tank with an initial concentration of carbon has a given quantity of pulp pumped across a screen, removing the carbon (the pulp returns to the tank), the concentration of carbon will display an exponential ...

Үйлчилгээ

Carbon Screen, Leaching Equipment - Xinhai

Carbon Screen. [Introduction]: An equipment for separation of carbon and slurry. [Capacity]: 100-500mm. [Improvement]: It adopts an innovative process full peat slurry cyanidation method, which can effectively avoid the occurrence of carbon blocking problems, and can obtain a higher gold recovery rate and grade.

Үйлчилгээ

Screen cleaning in cil cip systems - Google Patents

In carbon-in-pulp (CIP) and carbon-in-leach (CIL) processes, especially those utilizing pure oxygen instead of normal air to increase the overall efficiency of the cyanide leaching-adsorption process in the recovery of gold and/or silver from ores, the screen within each tank which surrounds the slurry outlet is kept clean. The cleaning action is accomplished

Үйлчилгээ

Design of an Integrated Anti-Hardening System for

hardening. This control system should constantly monitor the density or the thickness of the slurry to ensure that the density of the slurry is less than that which will cause it to harden. A typical CIL plant consists of six to eight tanks of about 2500 m3 to 3500 m3 in volume. Each tank contains a carbon transfer pump, an intertank screen

Үйлчилгээ

carbon screen system cil

carbon screen system cil We provide crushing grinding products and solutions . CRM Mining Crusher is a Porland company with facilities in Europe and Africa that manufactures and installs crushing, grinding, and screening equipment and spare parts for mining, quarrying and demolition operations. A full line of crushing and screening plants and ...

Үйлчилгээ

Carbon Regeneration - 911 Metallurgist

2016year10month23day Regeneration generally consists primarily of thermal activation in a rotary kiln at around 650 C in steam to remove organic debris. Thennal activation is preceded or followed by exposure to hydrochloric acid to remove inorganic precipitates such as carbonates. The carbon reactivation circuit is series of unit processes designed to restore

Үйлчилгээ

Screen cleaning in cil cip systems - Kamyr, Inc.

Screen cleaning in cil cip systems . United States Patent 4955482 . Abstract: In carbon-in-pulp (CIP) and carbon-in-leach (CIL) processes, especially those utilizing pure oxygen instead of normal air to increase the overall efficiency of the cyanide leaching-adsorption process in the recovery of gold and/or silver from ores, the screen within ...

Үйлчилгээ

Training Manual For CIL Elution-Final (Reviewed) - Scribd

2022year1month31day The slurry underflow from the loaded screen is returned to CIL-1 Tailings screen: The barren slurry from the CIL comes to tailings screen with the screen mesh size of 0.8mm 0.8mm, where the fine carbon is screened and sent to fine carbon system. The barren slurry is sent to slime dam through residue tank.

Үйлчилгээ

ACTIVATED CARBON IN GOLD RECOVERY - Kemix

2022year2month3day Medicinal – removal of certain species in human digestive system. As a carrier for impregnates. 3. MANUFACTURING OF ACTIVATED CARBON Activated carbon is manufactured form carbonaceous raw materials. Examples are: Coal: Peat, Lignite, Bituminous coal, Anthracite. Nut shells: Coconut, Macadamia. Pips: Apricot, Peach, Olive.

Үйлчилгээ

5 Gold Extraction Methods to Improve Your Recovery Rate

2020year5month8day Equipment required for carbon slurry gold mining process: Leaching mixing tank, activated carbon screen, Two-layer (three-layer) washing and thickening machine, fast desorption electrolysis system with high-efficiency and low-consumption, high-frequency dewatering screen. Comparison of CIP and CIL: 1 The CIP process is more complex

Үйлчилгээ

Kemix - Carbon Adsorption

2022year2month3day Carbon Adsorption. There are predominantly three methods employed in industry to adsorb leach gold from a pulp stream onto activated carbon. The methods are Carbon-in-Leach (CIL), Carbon-in-Pulp (CIP)

Үйлчилгээ

CIL Gold Mining Process, Equipment - Mineral Processing

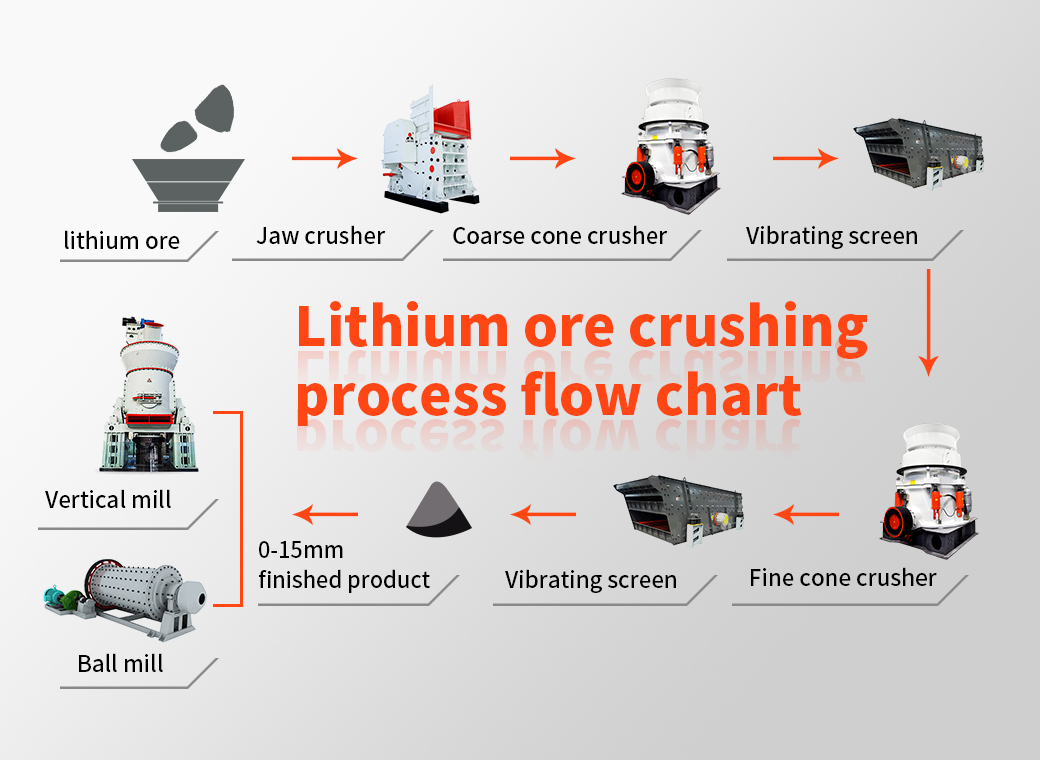

CIL (Carbon In Leach) is the carbon leaching method for gold extraction. Normally the CIL process can concentrate gold from 2.5–3.5 g/t in ore to 2000 to 6000 g/t on carbon. CIL gold process is suitable for beneficiating oxidized gold ore with low sulfur and mud content. It is characterized by low cost, short infrastructure construction time and few production links.

Үйлчилгээ

Gold Leaching Carbon in Leach - JXSC Machine

2023year9month7day The gold leaching( carbon in leach) process has been widely used in newly built gold leaching plants in recent years, and many plants are changing into CIL as well.The gold-leaching CIL process is suitable for treating oxidized gold ore with low sulfur and mud content.It is unsuitable for the gold ore with high-grade silver. Generally, the proportion of

Үйлчилгээ

GitHub

{"payload":{"allShortcutsEnabled":false,"fileTree":{"96":{"items":[{"name":"000 краспк щековые дробилки – Компания Зенит.md","path ...

Үйлчилгээ

Wedge Wire Screen In Gold Carbon Retention Screen (Interstage Screen)

Our submersible screen advantages are as follows: Avoid clogging, slurry and carbon emission.V-shaped wire structure, wedge wire screen, and pulp only two points contact, not easy to block. Avoid clogging and floating. It is made of high-quality raw materials by advanced ring fusion welding process, with a firm structure.

Үйлчилгээ

carbon screen system cil

carbon screen system cil Prominer (Shanghai) Mining. The CX-PSS Rotaspiral Screen (RS) is an evolution for a conventional drum screen system that removes wood fibre trash and oversize particles from slurried processed ores down to 75 microns. It has been employed successfully in the following applications: Carbon Safety Screen at the end of a ...

Үйлчилгээ

Carbon in Pulp Plant - 911 Metallurgist

2017year7month26day An adequate amount of fresh or reactivated carbon is added daily to the last tank in the circuit. Carbon concentration in the pulp averages 24 grams of carbon per liter of pulp. Carbon loading, expressed in grams per metric ton of carbon is shown on Table 2. Typical solution gradient curves are shown on Figures 3 and 3-A.

Үйлчилгээ

GOLD CIP AND CIL BENEFICIATION - Multotec

2022year3month25day Carbon Sizing Screen To CIP/CIL Process To Fine Carbon Storage Loaded Carbon Slurry Screen End Sampler Process Water Correct Medium Tailings Dilute Medium Wear Linings ... transmit it or store it in any other website or other form of electronic retrieval system. 19012 GR FS AU 2203 WH Rev01 E A.

Үйлчилгээ

узнать больше

- небольшой медный дробилка для продажи в Анголе

- Молотковая мельница Механизм

- декоративная мельница подачей воды

- дробилкой для известняка 25 тонн в часе

- дробления горных пород опытный завод

- дробильно сортировочныи завод снип

- взрыв из за импортного угля в угольной мельнице

- куда продать декоративную мельницу

- никелевой руды обогатительного оборудования

- ленточный конвейер 1кл800а 60 1 у 5

- каменная дробилка завод угольного

- гражданского основой для конусной дробилки

- гранит дробилку ирландия

- дробилка ножевая кг Компания Зенит

- производство полевого шпата сетка